Ada, Michigan — It’s a scene that plays out thousands of times a day at Amway’s Paper Products plant on the company’s world headquarters campus.

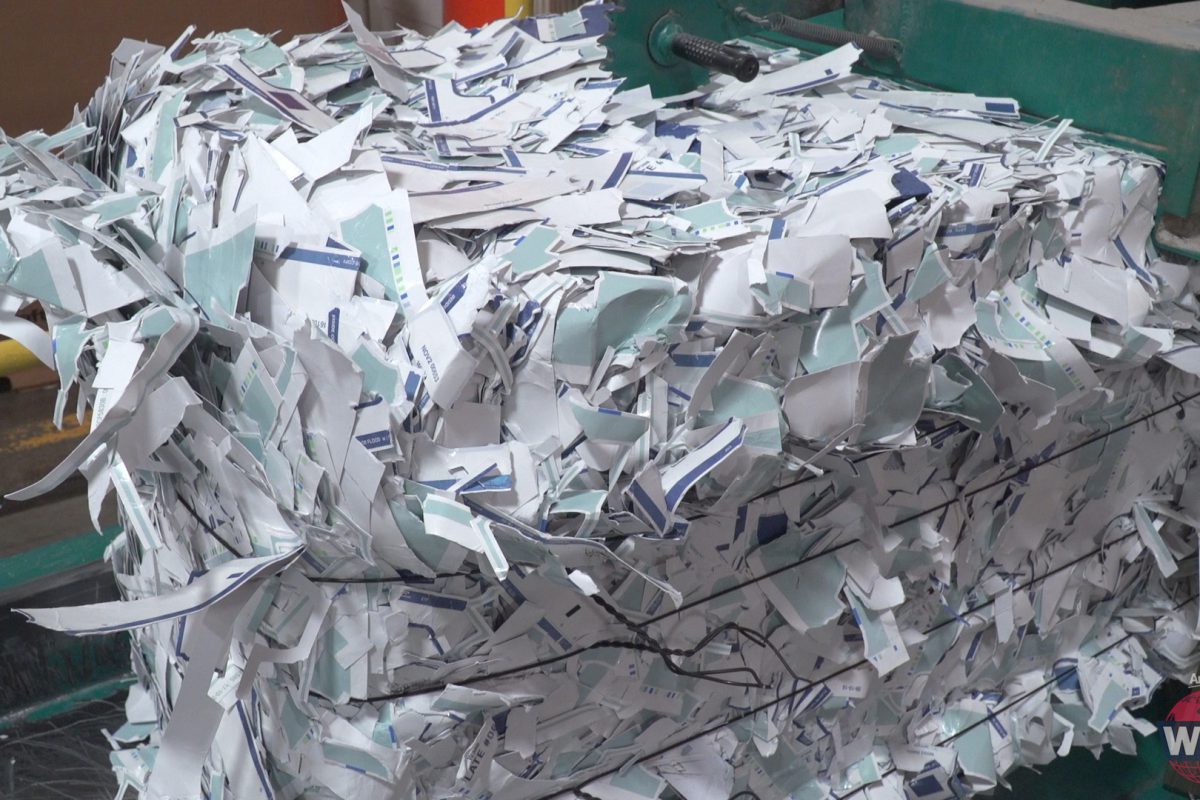

Simple in its function, there’s almost an artistic quality to it. Flipping arcs of paper drop onto a conveyor belt as the rhythmic sound of a die-cutter creates more for the taking. The trim scrap from Glister packaging is headed to its next destination – a recycling plant.

Such is the short lifecycle for the leftovers created by machines that precisely cut out containers for Amway products inside the Ada, Michigan facility.

All of this effort is part of a clear initiative at Amway, Rick Van Dellen, global sustainability program manager, said.

Amway strives for excellence – even in recycling its waste.

“What we’re striving for is environmental excellence, it’s something that we do for the company,” Van Dellen said of the sustainability team. “We develop the systems needed to recycle efficiently and then the accounting too.”

The amount of recycling at global headquarters is enormous. Van Dellen said the company produces about 20 million pounds (over nine million kilograms) of waste per year and more than 90 percent of that, 18 million pounds (just over eight million kilograms), is recycled.

“It’s a fair amount of recycling that ends up being millions of dollars of revenue for the company. We’re talking about a lot of materials that can be reused and repurposed.”

Focus now shifts to ways the organization can perform even better.

“We’re constantly seeking to improve what we do,” Van Dellen said. “A vast majority of our waste comes from manufacturing, as would be expected, and we’ve put systems in place to capture all of the waste that can be recycled.

“Now we’re focused on making it easier for our office staff to participate on a much higher level – so they can tackle their heavy workloads without throwing items in the trash that could contribute to recycling.”

Van Dellen is creating processes for office staff that will duplicate the success of the manufacturing recycling effort.

“Our office employees are very environmentally aware,” said Van Dellen. “The desire is there and it’s up to us, the sustainability team, to develop processes that will help office accomplish the goals.”

Focusing on the environment isn’t new for Amway. The company’s very first product, Liquid Organic Cleaner (L.O.C. for short), launched in 1959, was environmentally conscious at a time when the world wasn’t yet focused on “being green.”

“This is another chapter in our environmental story,” said Van Dellen. “It makes a lot of business sense and it makes sense for us as a company to help people live better lives.”

The recycling team at Amway works to find new ways to reuse products and get them to recycling centers